Expander has developed a portfolio of technologies that can produce “Fossil Free” Low Carbon Intensity Fuels

- “Drop In” compatible with current engines and infrastructure – zero adoption cost to end user

- Direct competitor to Renewable Diesel (HDRD) – with lower carbon intensity

- Low-cost cellulosic feedstock – not exposed to seed oils market pricing

- Lower airshed emissions and biodegradable

- No competition with food production

- Scalable: 100 BPD to 5,000 BPD (6 million to 300 million liters per year capacity)

![]() TAR-FREE BIOMASS GASIFIER TECHNOLOGY

TAR-FREE BIOMASS GASIFIER TECHNOLOGY

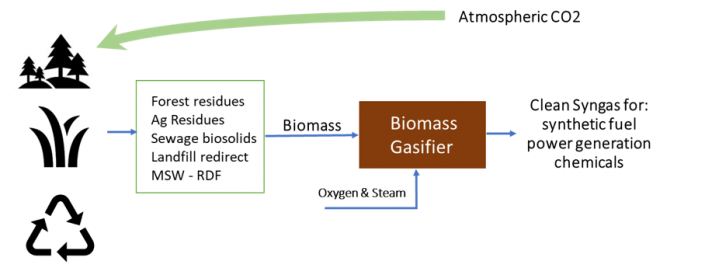

Core enabling technology for Biomass to Liquids (BTL) diesel production

Expander and Expander Technologies Inc. in collaboration with AirTechnic s.r.o of the Czech Republic have developed and co-patented a Biomass Gasifier that has proven to provide “tar free” syngas in long term service from non-food cellulosic feedstock.

![]() ENHANCED BIOMASS TO LIQUIDS (EBTL) TECHNOLOGY

ENHANCED BIOMASS TO LIQUIDS (EBTL) TECHNOLOGY

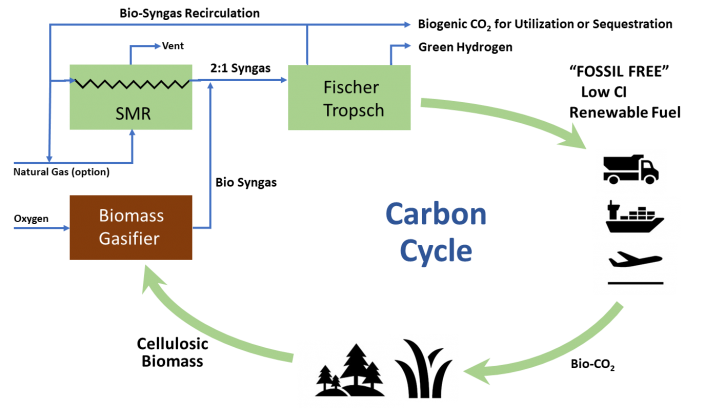

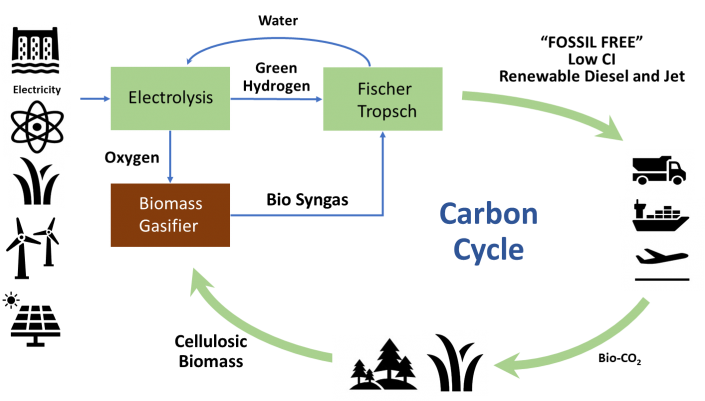

Enhanced Biomass to Liquids (EBTL™) is a patented process to integrate gasification, hydrogen generation and Fischer Tropsch conversion of biomass to produce “Fossil Free” Renewable Low Carbon Intensity Fuels Bio-SynDiesel® and Bio-SynJet®.

Expander’s EBTL™ process captures and sequesters biogenic CO2 at a fraction of the energy cost of comparable processes (CCS or DAC)

Independent 3rd party verification using ISO 14040 / GHGenius: Life Cycle Carbon Intensity as low as 44 gCO2e/MJ – possible through application of Expander’s patented technologies with renewable electricity and carbon sequestration.

No Food Competition – feedstock is cellulosic: wide variety of forestry residues, agricultural residues, landfill redirect, municipal sludge, etc.

“Drop-in” Diesel or Jet fuel – 100% compatible with existing engines and infrastructure.

![]() BIOMASS ELECTROLYSIS TO LIQUIDS TECHNOLOGY

BIOMASS ELECTROLYSIS TO LIQUIDS TECHNOLOGY

BETL™ is a patented process which integrates gasification, hydrogen generation and Fischer Tropsch conversion of biomass to synthetic diesel using low carbon intensity electricity generated hydrogen to produce a “Fossil Free” Renewable and Low Carbon Intensity Fuel.